Have you ever wondered how your bike stops so effectively, even at high speeds? The answer lies in its braking system, a critical part that ensures your safety on the road. Whether you’re a seasoned rider or a beginner, understanding how these components work can make a huge difference in your bike’s performance and your confidence on the road.

From early designs like spoon brakes to modern disc brakes, braking technology has come a long way. Today, brands like Brembo and Nissin lead the way in producing high-quality parts that deliver reliable stopping power. Knowing how to evaluate and maintain these components can save you time, money, and ensure your bike is always in top condition.

In this guide, we’ll explore the key elements of a bike’s braking system, from brake pads to calipers and discs. You’ll also learn how to spot potential issues and make informed decisions when upgrading or replacing parts. Let’s dive in and ensure your bike is as safe as it is powerful.

Key Takeaways

- Understand the importance of your bike’s braking components for safety.

- Learn about the evolution of braking technology from early designs to modern systems.

- Discover the role of brands like Brembo and Nissin in producing reliable parts.

- Gain insights into evaluating and maintaining your bike’s braking system.

- Get tips on upgrading or replacing parts for better performance.

Introduction: Exploring Motorcycle Brake Systems

What makes your bike stop safely, even in challenging conditions? The answer lies in its braking system, a combination of parts working together to ensure your safety. Whether you’re riding on busy city streets or open highways, understanding these components is essential.

This guide provides technical and practical advice to help you make informed decisions. From brake pads to calipers, we’ll cover everything you need to know. You’ll also learn how to evaluate quality and maintain your bike’s stopping power.

Scope of the Guide

We’ll explore the evolution of braking technology, from early designs to modern innovations. You’ll gain insights into the roles of disc brakes, pistons, and other key components. This guide also highlights the importance of safety certifications and compliance with Australian standards.

Why Brake Safety Matters

Did you know that approximately 70% of braking effort comes from the front brake? This fact underscores the need for reliable components. Proper maintenance can significantly improve your bike’s performance and ensure your safety on the road.

Whether you’re a seasoned rider or a beginner, understanding your bike’s braking system is crucial. It’s not just about stopping power; it’s about confidence and control. Let’s dive deeper into what makes these systems so vital.

History and Evolution of Motorcycle Brake Technology

Ever wondered how braking technology evolved to keep riders safe? From humble beginnings to cutting-edge innovations, the journey of bike stopping mechanisms is a fascinating tale of engineering and safety. Let’s take a closer look at how these systems developed over time.

Early Innovations and Spoon Brakes

The first braking systems were simple yet effective. In 1899, the Royal Riley Tricycle introduced the spoon brake, a design where a metal spoon pressed against the wheel to create friction. While innovative for its time, it had limitations, especially in wet conditions.

By the early 1900s, band brakes emerged. These used a steel band wrapped around the wheel hub, offering better stopping power. However, they still struggled with heat and wear, prompting further advancements.

The Rise of Disc and Drum Brakes

Drum brakes became popular in the mid-20th century. They used shoes inside a drum to create friction, providing more consistent performance. Models like the Lambretta TV125 Series 3 showcased this technology, making it a standard for decades.

The real game-changer came with disc brakes. Introduced in the 1960s, they used a rotor and caliper system for superior stopping force. The Honda CB750, released in 1969, was the first production bike to feature disc brakes on both wheels, setting a new benchmark.

Modern advancements like ABS, introduced by BMW in 1988, have further enhanced safety. These systems prevent wheel lock-up, ensuring better control in emergencies. Today, braking technology continues to evolve, blending history with innovation to keep riders safe on the road.

Understanding Key Components of Brake Systems

What’s the secret behind your bike’s smooth and reliable stopping power? It all comes down to the intricate design and functionality of its brake components. From pads to discs and calipers, each part plays a vital role in ensuring your safety on the road.

Brake Pads and Discs

Brake pads are the unsung heroes of your bike’s stopping mechanism. They create friction against the disc, converting kinetic energy into heat. Different materials, like organic, sintered, and carbon, offer varying levels of durability and performance. For example, sintered pads excel in wet conditions, while carbon pads are ideal for high-speed racing.

Discs, on the other hand, come in designs like floating and wavy. Floating discs reduce vibration and improve heat dissipation, ensuring consistent performance. Wavy discs, often seen in high-performance models, enhance airflow and cooling, making them perfect for demanding rides.

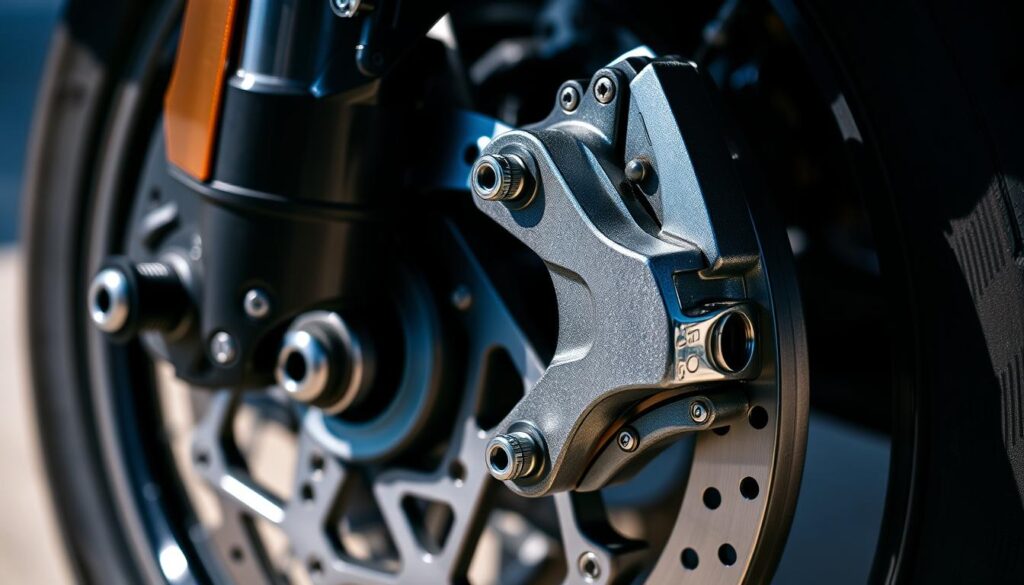

Calipers and Mounting Methods

Calipers house the pistons that press the pads against the disc. Their mounting method—axial or radial—affects braking feel and efficiency. Axial mounting is simpler and cost-effective, while radial mounting reduces torsional flex, offering a crisper and more progressive braking experience.

Modern designs from brands like Brembo and Nissin often feature radial-mounted calipers, which are preferred for their precision and durability. These innovations ensure your bike stops smoothly, even under heavy use.

| Pad Material | Best Use Case | Durability |

|---|---|---|

| Organic | Everyday riding | Moderate |

| Sintered | Wet conditions | High |

| Carbon | High-speed racing | Exceptional |

Choosing the right components is crucial for your bike’s safety and performance. Whether you’re upgrading or maintaining your system, understanding these parts ensures you’re always in control on the road.

How to Evaluate Used Motorcycle Brake Systems

How can you ensure your bike’s stopping power remains reliable over time? A thorough inspection of its braking components is essential. Knowing what to look for can save you from costly repairs and ensure your safety on the road.

Identifying Quality Indicators

Start by checking the brake pad thickness. Worn pads reduce stopping power and can damage the disc. Look for even wear patterns, as uneven wear may indicate caliper issues. For rotors, inspect for grooves, warping, or cracks, which can compromise performance.

Next, examine the caliper pistons for smooth movement. Sticking pistons can lead to uneven pad contact and reduced braking efficiency. Don’t forget to check the brake fluid for clarity and consistency. Contaminated fluid can affect the entire system.

Spotting Wear and Tear

Look for signs of corrosion on metal parts, especially in older models. Rust can weaken components and reduce their lifespan. Pay attention to the disc surface; excessive heat can cause discoloration, indicating potential overheating issues.

Certifications like TÜV ensure that parts meet stringent safety standards. Always verify these credentials when evaluating used components. As stated in federal guidelines, proper testing ensures that braking systems meet safety and performance requirements.

“A well-maintained braking system is your first line of defence on the road.”

Finally, ensure all parts are compatible. Mismatched components can lead to suboptimal braking and increased wear. By following these steps, you’ll maintain control and safety, ensuring your bike is always ready for the ride ahead.

Comparing Front and Rear Brake Setups

Why does your bike’s front brake handle most of the stopping power? The answer lies in the design and dynamics of your braking system. Understanding the roles of front and rear brakes can help you optimize your bike’s performance and safety on the road.

Front Brake Dynamics

The front brake typically handles around 70% of the braking effort. This is due to the weight transfer that occurs when you apply the brakes. As the bike slows, the front wheel bears more weight, increasing its grip and stopping power.

Modern disc brake systems on the front are designed to handle this load. They often feature larger rotors and multi-piston calipers for better heat dissipation and consistent performance. This setup ensures you have maximum control, especially in emergency situations.

Rear Brake Considerations

While the rear brake contributes less to stopping power, it plays a crucial role in stability. It’s particularly important in low-speed maneuvers or when navigating slippery surfaces. The rear brake pad and rotor are usually smaller, as they don’t need to handle the same level of force.

Different bike models, like cruisers and sports bikes, have varying rear brake setups. For example, cruisers often use drum brakes for simplicity, while sports bikes rely on lightweight disc systems for precision.

By understanding these dynamics, you can better evaluate your bike’s braking system. Whether you’re upgrading or maintaining it, knowing the roles of front and rear brakes ensures you stay safe and in control on the road.

Exploring Different Types of Brake Systems

When it comes to stopping your bike, not all braking mechanisms are created equal. Over the years, disc brakes and drum brakes have emerged as the two primary types, each with its own set of advantages and limitations. Understanding these differences can help you make informed decisions about your bike’s performance and safety.

Disc Brakes vs Drum Brakes

Disc brakes have become the standard for modern bikes, especially in high-speed and race conditions. They use a rotor and caliper system to create friction, offering superior heat dissipation and consistent braking power. This design ensures that your bike stops smoothly, even under heavy use.

On the other hand, drum brakes were once the go-to option for both front and rear wheels. Today, they are mostly used for rear setups due to their simplicity and cost-effectiveness. While they may not offer the same level of performance as disc brakes, they are still reliable for everyday riding.

| Feature | Disc Brakes | Drum Brakes |

|---|---|---|

| Heat Dissipation | Excellent | Moderate |

| Response Time | Short | Longer |

| Maintenance | Higher | Lower |

| Cost | Higher | Lower |

Disc brakes are particularly effective in wet conditions, where their design prevents water from affecting braking performance. Drum brakes, however, can struggle in such conditions due to their enclosed nature, which can trap water and reduce friction.

Historically, drum brakes were widely used in models like the Lambretta TV125 Series 3. However, the introduction of disc brakes in the 1960s, particularly in the Honda CB750, marked a significant shift in design and functionality. Today, disc brakes are preferred for their reliability and efficiency, especially in sports and touring bikes.

Understanding these types of brakes is crucial when evaluating a used system. Whether you’re upgrading or maintaining your bike, knowing the strengths and weaknesses of each can help you ensure optimal performance and safety on the road.

Used Motorcycle Brake Systems: What to Look For

What should you consider when inspecting a second-hand braking setup? Ensuring the system is in good condition is crucial for your safety on the road. From material quality to design integrity, every detail matters.

Assessing Material and Design Quality

Start by examining the brake pad and disc for wear. Worn pads reduce stopping power and can damage the rotor. Look for even wear patterns, as uneven wear may indicate caliper issues. Ensure the materials are free of asbestos, which was phased out in the 1990s.

For discs, check for grooves, warping, or cracks. These issues can compromise performance and safety. Modern discs are often made from hardened stainless steel, which is rust-resistant and durable. Avoid cast iron rotors, as they are more prone to warping.

Inspect the caliper pistons for smooth movement. Sticking pistons can lead to uneven pad contact and reduced braking efficiency. Rebuild kits are available if you notice issues like leaks or corrosion.

Importance of Safety Certification

Safety certifications like TÜV ensure that parts meet stringent standards. For example, TRW’s brake pads and discs come with TÜV certification, guaranteeing they comply with road traffic requirements. Always verify these credentials when evaluating used components.

Check if the design complies with the latest safety standards. Modern systems often feature innovations like CNC-machined slots and cooling edge cuts, which enhance performance and durability. These details can make a significant difference in your bike’s braking efficiency.

Finally, ensure all parts are compatible with your bike. Mismatched components can lead to suboptimal braking and increased wear. Manufacturer documentation and colour-matched accessories are good indicators of a trusted product.

| Component | Key Checkpoints |

|---|---|

| Brake Pad | Thickness, wear pattern, material |

| Disc | Surface condition, material, heat tolerance |

| Caliper | Piston movement, leaks, corrosion |

| Certification | TÜV or other safety standards |

By following these steps, you can ensure your brake system is reliable and safe. Whether you’re upgrading or maintaining your bike, these tips will help you stay in control on the road.

Maintenance Tips and Best Practices

Keeping your bike’s stopping power reliable requires consistent care and attention. Regular maintenance not only ensures safety but also extends the lifespan of your brake system. Here’s how you can keep everything in top shape.

Routine Inspections and Cleaning

Start by checking your brake pads for wear. If they’re thinner than 2mm, it’s time for a replacement. Uneven wear patterns could indicate issues with the caliper, so inspect it for smooth movement and signs of corrosion.

Clean your discs regularly to remove dirt and debris. Use a soft brush and a mild cleaner to avoid damaging the surface. For calipers, apply a high-temperature grease to prevent seizing and ensure optimal performance.

Brake Fluid and Upkeep Essentials

Your brake fluid plays a crucial role in stopping power. Check the reservoir regularly to ensure levels are above the minimum mark. If the fluid appears dark or cloudy, it’s time for a bleed. Aim to do this every two years or as recommended by your manufacturer.

Use only high-quality fluid that meets your bike’s specifications. Contaminated or old fluid can lead to reduced braking efficiency and even failure during hard stops.

“Regular maintenance is the key to safety and reliability on the road.”

Here’s a quick checklist for your routine maintenance:

- Inspect brake pads and discs for wear and damage.

- Clean and lubricate calipers to prevent seizing.

- Check and replace brake fluid as needed.

- Follow manufacturer service intervals for optimal performance.

By following these steps, you’ll ensure your bike’s brake system remains reliable and safe. Proper care not only enhances performance but also gives you peace of mind on every ride.

TRW and Other Leading Brands in Brake Components

When upgrading your bike’s stopping power, choosing the right components is crucial. TRW stands out as a trusted name in the industry, offering a wide range of high-quality parts designed for safety and performance. Their products are engineered to meet rigorous standards, ensuring reliability on the road.

Overview of TRW’s Product Range

TRW provides a comprehensive portfolio of brake components, including pads, discs, hoses, and accessories. Their brake pads are available in 12 different friction compounds, catering to various riding conditions. Whether you’re looking for organic or carbon pads, TRW has options that enhance performance and durability.

Their disc range covers over 2,000 models, with a service life up to 30% longer than many competitors. The precision in thickness variation ensures smooth operation, reducing vibrations and improving control. Additionally, TRW’s steel braided hoses are compatible with ABS and Dual Combined Brake systems, offering flexibility and reliability.

Technological Innovations and Certifications

TRW is known for its innovative solutions, such as the patented NRS retention system. This technology ensures secure pad attachment, reducing noise and enhancing longevity. All TRW products intended for public use come with TÜV certification, guaranteeing compliance with safety standards.

Their Varioflex steel braided brake line system allows for custom connections and lengths, available in six colours. This flexibility ensures compatibility with a wide range of bike models, making TRW a versatile choice for riders.

| Feature | TRW | Other Brands |

|---|---|---|

| Product Range | Comprehensive (pads, discs, hoses) | Limited options |

| Certifications | TÜV certified | Varies |

| Innovation | NRS retention system | Standard designs |

| Compatibility | Over 6,000 models | Fewer models |

Choosing TRW means investing in a system that prioritises safety, innovation, and compatibility. Their commitment to quality ensures your bike performs at its best, no matter the conditions.

Upgrading and Customising Your Brake System

Enhancing your bike’s stopping power can transform your riding experience. Upgrading to aftermarket parts not only improves performance but also allows for personalisation. Whether you’re a casual rider or a track enthusiast, customising your brake system can make a significant difference.

Aftermarket Options and Accessories

Aftermarket parts offer a range of benefits, from improved braking response to enhanced durability. TRW’s steel-braided lines, for example, provide better resistance to corrosion and abrasion compared to standard rubber hoses. These upgrades are particularly effective in high-performance scenarios.

Customisation options are also plentiful. You can choose colour-matched brake levers or bespoke hose designs to match your bike’s aesthetic. These accessories not only look great but also contribute to a more personalised riding experience.

Installation and Tuning Tips

Proper installation is key to achieving optimal performance. Always use a torque wrench to tighten fittings to the specifications outlined in your bike’s manual. This ensures safety and reliability.

For ABS-equipped bikes, pay attention to the layout of the brake lines. The Race layout, for instance, is designed to meet ACU racing regulations and offers specialised benefits for competitive riders.

“Upgrading your brake system is one of the most cost-effective ways to improve your bike’s performance.”

If you’re not confident in your DIY skills, consider professional installation. Experts can ensure that all components are correctly fitted and tuned, giving you peace of mind on the road.

| Component | Benefit |

|---|---|

| Steel-Braided Lines | Improved durability and braking response |

| Colour-Matched Levers | Enhanced aesthetics and personalisation |

| Race Layout Lines | Specialised performance for competitive riding |

By combining upgraded parts with your existing system, you can create a tailor-made solution that meets your specific needs. Whether you’re aiming for better control or a unique look, these upgrades can elevate your riding experience.

Safety and Compliance in Australia

Ensuring your bike’s stopping power meets safety standards is non-negotiable. In Australia, compliance with road safety regulations is mandatory for all vehicles, including their brake systems. Whether you’re upgrading or replacing parts, understanding these requirements is essential for your safety on the road.

TÜV Certificates and Standards

TÜV certification is a globally recognised mark of quality and safety. For brake pads, discs, and other components, this certification ensures they meet stringent performance and durability standards. When purchasing aftermarket parts, always look for the TÜV mark to guarantee compliance with international safety norms.

Genuine parts often come with TÜV certification, but many aftermarket options also meet these standards. This certification is particularly important for high-performance components, as it verifies their ability to handle extreme conditions without failure.

Meeting Australian Road Safety Regulations

In Australia, all brake systems must comply with the Australian Design Rules (ADRs). These regulations cover everything from disc thickness to pad material, ensuring that every part meets the necessary safety criteria. Non-compliance can lead to serious legal and safety issues.

When selecting components, verify that they adhere to ADRs. This includes checking for compliance notices and ensuring the parts are approved by the Department of Transport. Using non-compliant parts not only risks your safety but also voids your bike’s warranty.

“Safety-certified parts are your best defence against component failure and accidents.”

Here’s a quick comparison of certified vs. non-certified parts:

| Feature | Certified Parts | Non-Certified Parts |

|---|---|---|

| Compliance | Meets ADRs and TÜV standards | May not meet safety regulations |

| Performance | Tested for reliability and durability | Untested, higher risk of failure |

| Warranty | Supported by manufacturer | Voids warranty |

Prioritising safety-certified products ensures your bike performs at its best while keeping you protected. Always verify certifications and adhere to local regulations when upgrading or replacing your brake system.

Conclusion

Making informed decisions about your bike’s stopping power ensures safety and performance on the road. Throughout this guide, we’ve explored the evolution of braking technology, key components like discs and pads, and the importance of regular maintenance. Evaluating the condition and certification of used parts is crucial for reliability.

Trusted aftermarket brands like TRW offer high-quality components that enhance your system’s efficiency. Always ensure your upgrades comply with Australian safety regulations to maximise protection. Proper maintenance and component matching can significantly extend the lifespan of your brake setup.

By following these guidelines, you’ll have the confidence to choose the right parts for your bike. For further insights, consider professional inspections and trusted resources. Your safety and performance depend on it.